The changing passage of personnel entering the clean production area should be set up with corresponding changing facilities according to the nature of production, product characteristics, product requirements for environmental level, etc., and the airflow organization, setting pressure difference and monitoring devices should be reasonably designed to meet the requirements of pharmaceutical GMP for purified changing.

Usually the following factors must be taken into account:

Setting of changing rooms

Different stages of dressing are separated by rooms, such as several rooms according to changing shoes (taking off outer clothes), wearing clean clothes (wearing sterile underwear, sterile outer clothes), airlock (hand washing, hand disinfection), etc. The last airlock, play a role in isolating the airflow between the dressing area and the production area.

Classification of dressing

The new GMP requires that “the static level of the back section of the dressing is consistent with the clean level of its corresponding clean area”. The back section of the dressing refers to the wearing of clean clothing (wearing sterile outer clothing) and the subsequent airlock, the cleanliness level of these areas is consistent with the level of the production area they serve. The front section of the dressing area, as an auxiliary area for purifying dressing, needs to be fed with air filtered by HEPA filter, a certain number of air changes, and a certain pressure gradient, but it belongs to the unclassified area. the FDA has a proper name CNC, that is, Controlled NotClassified, also known as Control NotClassified area.

The pressure difference value of the dressing area

Dressing area as a channel for personnel to enter and exit the clean production area, the pressure difference (airflow direction) basically flows from the higher level area to the lower level area. The pressure difference between each adjacent airlock room is 5Pa, so that the accumulated pressure difference between clean and non-clean areas will not be too high. As long as the pressure difference between different clean areas and clean and non-clean areas is controlled at more than 10Pa, such as the pressure difference is too large, it will cause the increase of air leakage through the doorway, and at the same time, the strength requirements of the building partition should be increased.

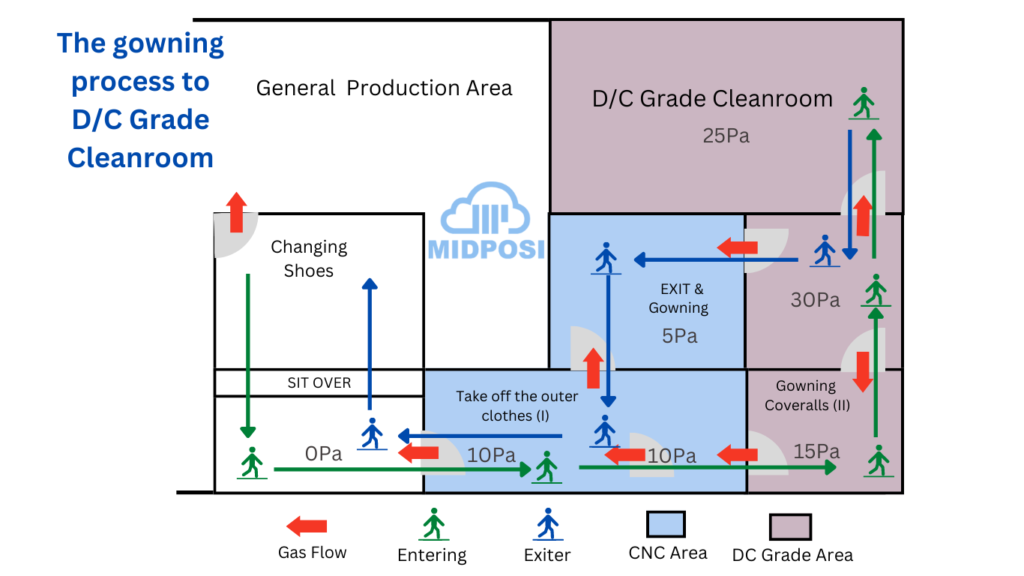

The gowning process to D/C Grade Cleanroom

Description:Changing the last air lock according to the positive pressure design, changing channel set up special exit channel, the exit channel according to the control of non-classification area (CNC) partition, air are filtered through the high-efficiency filter, there is a certain number of air changes and differential pressure, the relative undressing room for negative pressure design, in order to block the process of undressing particles generated by the airflow to bring out the possibility of changing area.

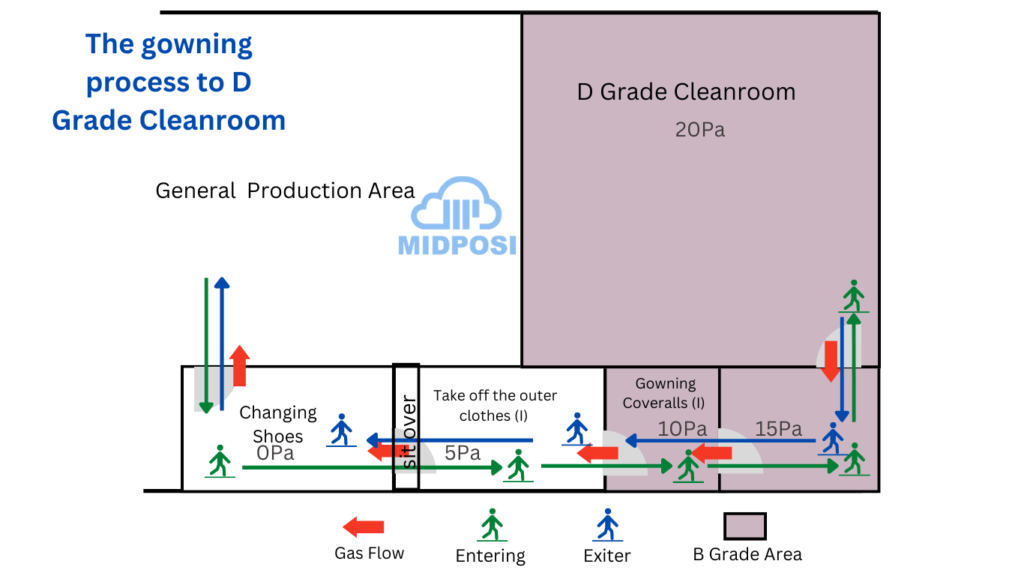

The gowning process to D Grade Cleanroom

4

Description:In order to prevent outside air interference in the general area, the stripping room is separated from the dressing room by a door. There are high-efficiency filters in the stripping room, and there is a certain number of air changes, which are considered according to the control non-classification area (CNC). The dressing room and the undressing room maintain a minimum pressure difference of 10 Pa.

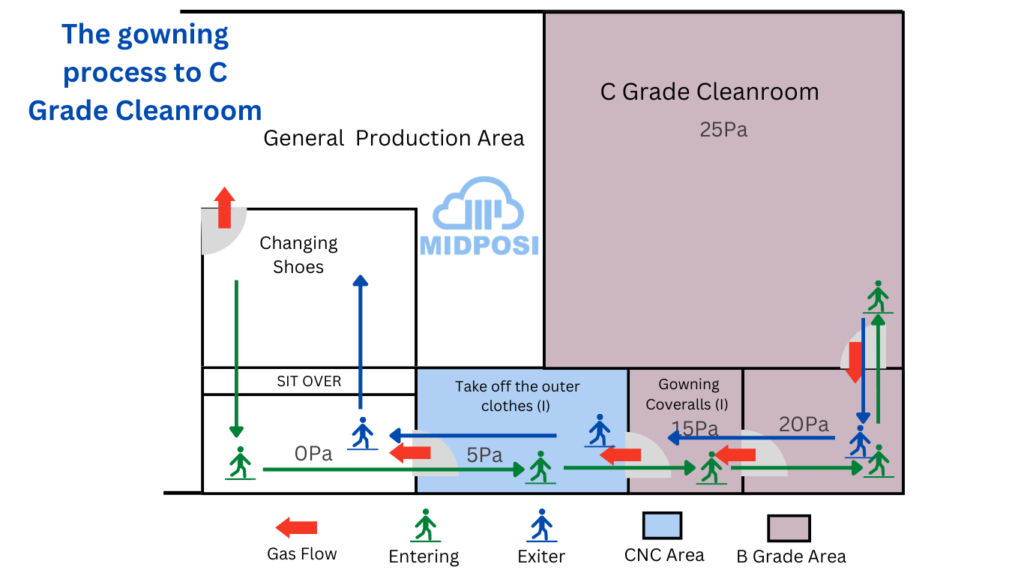

The gowning process to C Grade Cleanroom

Description:It is simpler to enter the D-level area to change clothes, change shoes and take off outer clothes in a space to complete, with SIT-OVER in the middle to separate the front and rear parts. Dressing room according to the D-class design, its pressure difference with the outer clothing room can be controlled at 10Pa. Its pressure difference with the air lock is kept at 5Pa.

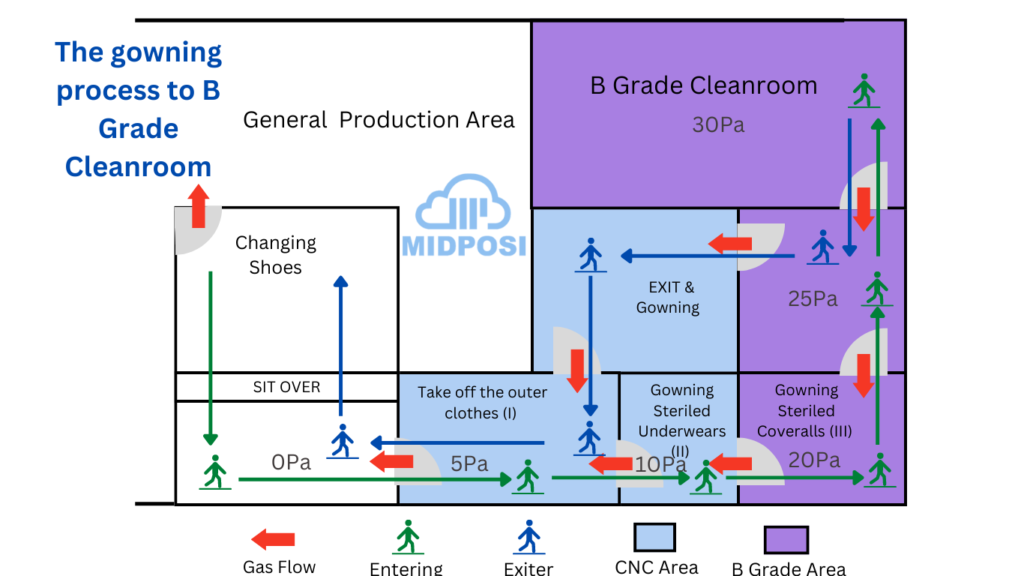

The gowning process to B Grade Cleanroom

Description:In order to prevent the outside general area air interference, from the first gowning to the third gowning to maintain the air pressure increment, take off the outer clothing room has a high efficiency filter, a certain number of air changes, according to the control of non-classified area (CNC) consideration. The exit channel design is added.

How Is Proper Gowning For Class B Area?

Please refer to the following video.

- Enter the B-level Buffer Room

- Take off C-level work shoes and put them on the shoe rack

- Enter the sterile gowning room

- Press the spray bottle containing the disinfectant to disinfect the hands

- Select from the clothing rack the appropriate size of Class B sterile gown, eye goggles and Class B sterile boots

- Place them on the isolation bench

- Press the spray bottle containing the disinfectant to disinfect the hands

- Unzip the large compartment of the sterile gown bag and take out the hooded sterile gown from the bag

- By the collar of the inside of the pull ring to pick up the clothes lift shaking unfold

- Open the zipper, taking care not to touch other parts of the zipper other than the head

- Turn out the upper part of the garment, adjust the outer garment to a height suitable for you to wear

- carefully put one leg through the pants; hands do not release

- Put the other leg into the other pants tube

- Lift the jacket up with both hands and find a cuff first by looking into the mirror

- open the sleeve tube and put on, while the thumbs of both hands through the sleeve end of the pull ring

- Adjust the cap, adjust the process of hand not to touch the outer surface of the clothing and skin

- Adjust the waistline and put the waistline into the garment

- Fasten the zipper

- look in the mirror and fasten the three buttons on the collar from bottom to top

- Press the spray bottle containing disinfectant to disinfect the hands

- Take out the mask and touch only the lacing of the mask with your hands

- Reach the inside surface of the mask and adjust the mask closer to the body

- Put on the mask and adjust the position of the marble buckle until there is no gap between the mask and the face

- Press the spray bottle containing the disinfectant to disinfect the hands

- Take out the protective goggles from the bag, and only touch the goggle strap with your hand when taking out

- Adjust the position of the goggles in front of the mirror and fasten the clasps to the back

- Press the spray bottle containing the disinfectant to disinfect the hands

- Open the boot bag, lift the inner surface of the boot and remove them

- Open the buckle and pull the zipper to the bottom

- Put the foot into the high top boot and pull open the buckles on both sides of the pants

- Fasten the pair of buttons on the front edge of the leg and tighten the leg

- Hook your fingers on the two pull tabs at the top of the shoe to close the zipper of the stilettos

- Fasten the snap at the end of the zipper

- Wear the high boots feet can step over the isolation bench, step on the inside of the floor of the isolation bench

- The other foot above the isolation bench to maintain the suspension, take out the other boot

- Put on the other boot in the same way

- Check in the mirror that the eye mask, mask, cuffs and trouser cuffs are tightly fastened

- Press the spray bottle containing the disinfectant and spray the whole body in the order from top to bottom

- Put on the second layer of sterile gloves, adjust the gloves at the wrist and tie the cuffs in

- Press the spray bottle containing disinfectant to spray the hands to disinfect

- Completion of gowning

- Push open the airlock room door with your elbow and enter the class B sterile operation area.

If you need to inquire about the clean clothes in the video, please leave a message or call us. E-mail: 1@midpois.com