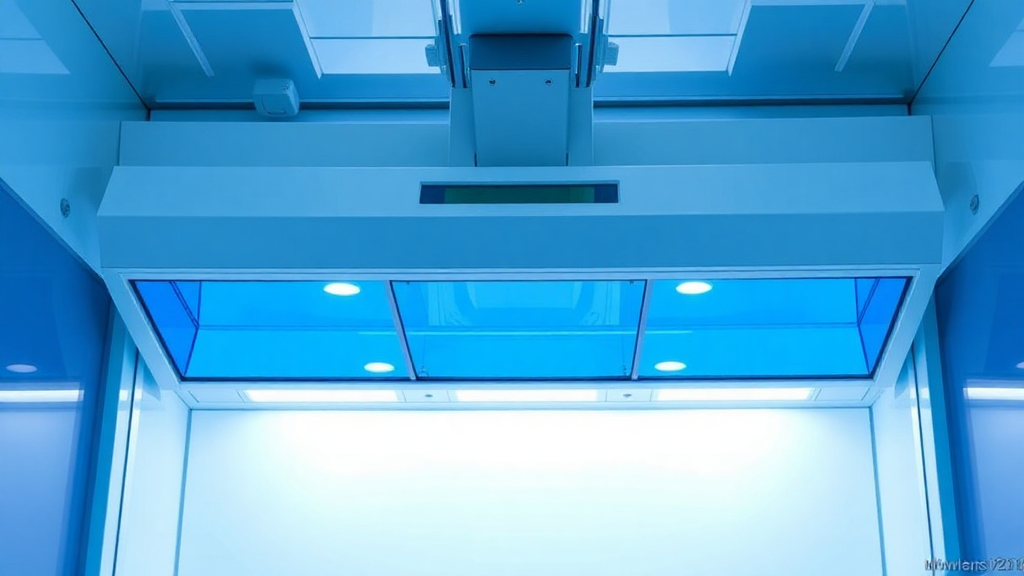

Ergonomic Cleanroom Hoods for Neck Strain Relief

In the demanding environment of cell therapy facilities, cleanroom hoods are essential for maintaining contamination control. However, traditional hood designs often lead to significant neck strain and discomfort for workers, impacting both productivity and health. This blog explores ergonomic solutions that enhance comfort without compromising safety, focusing on innovative cleanroom hoods designed to alleviate neck strain and improve overall worker well-being.

The Problem with Traditional Cleanroom Hoods

Standard cleanroom hoods, while effective for contamination control, frequently restrict mobility and cause discomfort. The rigid design and limited adjustability of these hoods force workers to maintain unnatural head positions for extended periods. This constant strain can lead to:

- Chronic neck pain

- Reduced range of motion

- Decreased productivity

- Increased risk of repetitive strain injuries

In cell therapy facilities, where precision and focus are paramount, these issues can have serious implications for both worker health and product quality.

Key Features of Ergonomic Cleanroom Hoods

Modern ergonomic cleanroom hoods address these challenges through innovative design features:

- Adjustable Fit: Hoods with customizable sizing ensure a proper fit for various head shapes and sizes, reducing pressure points and improving comfort.

- Lightweight Materials: Advanced fabrics maintain contamination control while significantly reducing the overall weight of the hood, lessening the burden on the neck and shoulders.

- Enhanced Mobility: Flexible materials and strategic seam placement allow for a greater range of motion, enabling workers to move their heads more freely without compromising the hood’s integrity.

- Improved Visibility: Larger, optically clear viewing panels reduce the need for excessive head movement, further alleviating neck strain.

- Breathable Design: Hoods with an air permeability of 5-10 CFM strike an optimal balance between contamination control and worker comfort, reducing heat buildup and improving overall wearability.

These features work in concert to create comfortable cleanroom PPE that doesn’t sacrifice safety for comfort.

Benefits of Upgrading to Ergonomic Hoods

Investing in ergonomic cleanroom hoods offers numerous advantages for cell therapy facilities:

- Enhanced Worker Satisfaction: Comfortable workers are happier workers, leading to improved job satisfaction and reduced turnover rates.

- Increased Productivity: By reducing physical strain and discomfort, workers can maintain focus and efficiency for longer periods.

- Improved Safety: Ergonomic hoods reduce the risk of repetitive strain injuries, potentially lowering workplace injury rates and associated costs.

- Better Contamination Control: Comfortable workers are less likely to adjust or fidget with their PPE, maintaining the integrity of the cleanroom environment.

- Long-term Cost Savings: While ergonomic hoods may have a higher initial cost, the long-term benefits in terms of productivity gains and reduced health-related absences can lead to significant savings.

How to Choose the Right Ergonomic Hood

Selecting the appropriate ergonomic cleanroom hood requires careful consideration of several factors:

- Material: Look for lightweight, breathable fabrics that meet your facility’s contamination control standards. Consider hoods with an air permeability rating of 5-10 CFM for optimal comfort and protection.

- Adjustability: Choose hoods with multiple adjustment points to ensure a custom fit for each worker.

- Compatibility: Ensure the hood integrates seamlessly with other required PPE, such as goggles or respirators.

- Visibility: Opt for designs with large, clear viewing panels to maximize the field of vision and reduce the need for excessive head movement.

- Durability: Consider the hood’s lifespan and resistance to cleaning procedures to ensure long-term value.

For a comprehensive guide on ergonomic considerations in cleanroom design, visit our ergonomics guide for more detailed information.

Case Study: Ergonomic Hoods in Action

A leading pharmaceutical company specializing in cell therapies recently implemented ergonomic cleanroom hoods across their facilities. The results were striking:

- 40% reduction in reported neck strain among cleanroom workers

- 15% increase in overall productivity

- 25% decrease in error rates during critical processes

These improvements were attributed to the enhanced comfort and mobility provided by the ergonomic hoods. Workers reported feeling less fatigued at the end of their shifts and experienced a noticeable reduction in neck and shoulder discomfort.

The company achieved these results by:

- Conducting a thorough assessment of worker needs and pain points

- Selecting ergonomic hoods with adjustable features and lightweight materials

- Providing comprehensive training on proper fitting and adjustment techniques

- Implementing a feedback system to continuously improve hood design and usage

This case study demonstrates the tangible benefits of investing in ergonomic cleanroom hoods, highlighting their potential to transform workplace comfort and efficiency in cell therapy facilities.

Frequently Asked Questions

What causes neck strain in cleanroom hoods?

Neck strain in cleanroom hoods is primarily caused by restricted mobility, heavy materials, and poor fit. Traditional hoods often force workers to maintain unnatural head positions for extended periods, leading to muscle fatigue and discomfort.

How do ergonomic hoods improve mobility?

Ergonomic hoods improve mobility through flexible materials, strategic seam placement, and adjustable designs. These features allow for a greater range of motion while maintaining the necessary level of contamination control.

Are ergonomic hoods compatible with other PPE?

Yes, most ergonomic cleanroom hoods are designed to be compatible with other PPE such as goggles, respirators, and face shields. It’s important to verify compatibility when selecting new hoods for your facility.

What industries benefit most from ergonomic cleanroom hoods?

While cell therapy facilities are prime candidates for ergonomic cleanroom hoods, other industries that benefit include pharmaceutical manufacturing, semiconductor production, and biotechnology research. Any sector requiring prolonged cleanroom work can see significant improvements from ergonomic PPE solutions.

In conclusion, ergonomic cleanroom hoods represent a significant advancement in contamination control technology, offering a solution that prioritizes both worker comfort and safety. By addressing the long-standing issue of neck strain associated with traditional hood designs, these innovative products pave the way for improved productivity, reduced injury rates, and enhanced overall performance in cell therapy facilities and beyond.

Investing in ergonomic cleanroom hoods is an investment in your workforce’s health and your facility’s efficiency. As the case study demonstrates, the benefits can be substantial and far-reaching.

To learn more about how ergonomic cleanroom hoods can benefit your facility, and to access detailed specifications for implementing these solutions, Download Ergonomic Design Specs today.