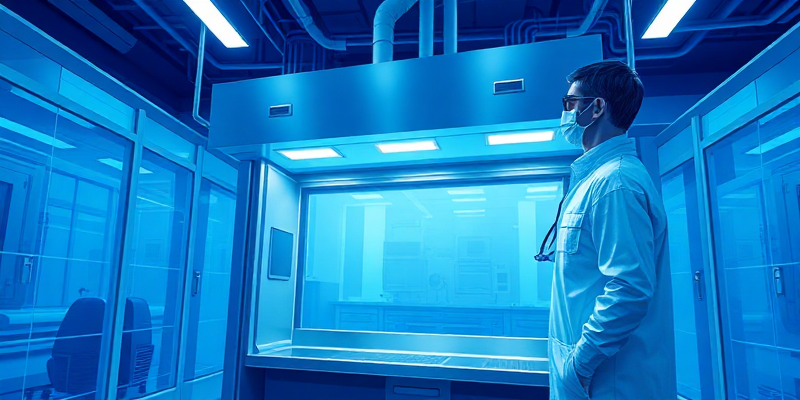

In the world of cleanroom environments, maintaining ISO Class 5 standards is crucial for ensuring optimal performance and contamination control. For HVAC engineers tasked with maintaining these critical systems, the right equipment and garments are essential. This case study explores how laminar flow hood garments are revolutionizing the way HVAC engineers approach maintenance in ISO Class 5 environments, ensuring compliance and enhancing efficiency.

Why ISO Class 5 Compliance Matters for HVAC Engineers

ISO Class 5 environments, also known as Class 100 cleanrooms, require exceptionally low particle counts – no more than 3,520 particles per cubic meter at 0.5μm and larger. For HVAC engineers, maintaining these stringent standards is paramount to the overall functionality and effectiveness of the cleanroom.

HVAC systems play a critical role in maintaining the cleanliness and environmental conditions within cleanrooms. Any contamination introduced during maintenance activities can compromise the entire environment, potentially leading to:

- Product contamination in pharmaceutical or semiconductor manufacturing

- Inaccurate research results in laboratory settings

- Increased risk of infections in medical facilities

By adhering to ISO Class 5 standards during maintenance procedures, HVAC engineers ensure the integrity of the cleanroom environment, safeguarding critical processes and products.

Key Features of Laminar Flow Hood Garments

Laminar flow hood garments are specifically designed to meet the rigorous demands of ISO Class 5 environments. These garments incorporate several key features that make them indispensable for HVAC engineers:

- Ultra-low particle emission: High-quality laminar flow garments emit ≤0.5μm particles, ensuring minimal contamination during maintenance activities.

- Advanced filtration materials: The fabrics used in these garments are engineered to trap particles effectively while allowing breathability for the wearer.

- Ergonomic design: Garments are designed to minimize movement-induced particle generation while providing comfort and flexibility for engineers during maintenance tasks.

- Integrated hood and face mask: Many laminar flow garments feature built-in hoods and face masks to provide comprehensive protection against contamination.

- Anti-static properties: To prevent the attraction and dispersion of particles, these garments often incorporate anti-static materials.

For more detailed information on laminar flow technologies and their applications, visit our laminar flow resources page.

Best Practices for Using Laminar Flow Hood Garments

To maximize the effectiveness of laminar flow hood garments and maintain ISO Class 5 compliance, HVAC engineers should follow these best practices:

- Proper donning and doffing procedures: Follow strict protocols for putting on and removing garments to minimize contamination risks.

- Regular inspection: Check garments for tears, wear, or damage before each use to ensure their integrity.

- Correct sizing: Ensure garments fit properly to minimize gaps and reduce the risk of particle penetration.

- Layering: Wear appropriate undergarments and follow cleanroom protocol for layering garments.

- Minimize movement: Once in the cleanroom, limit unnecessary movements to reduce particle generation.

- Proper storage: Store garments in a clean, designated area when not in use to prevent contamination.

- Training and education: Regularly update knowledge on cleanroom protocols and garment usage to stay current with best practices.

How Laminar Flow Garments Enhance Maintenance Efficiency

Implementing laminar flow hood garments in HVAC maintenance procedures offers several benefits that enhance overall efficiency:

- Reduced downtime: By minimizing contamination risks, these garments help reduce the need for repeated cleaning and decontamination procedures, allowing for faster maintenance completion.

- Improved safety: The comprehensive protection offered by laminar flow garments ensures the safety of both the engineer and the cleanroom environment.

- Streamlined processes: With proper training and use, these garments become an integral part of maintenance routines, streamlining the entire process.

- Cost-effectiveness: While the initial investment in high-quality garments may be higher, the long-term benefits in terms of reduced contamination incidents and improved efficiency often result in significant cost savings.

- Compliance assurance: Using appropriate garments helps ensure consistent compliance with ISO Class 5 standards, reducing the risk of costly violations or compromised environments.

Case Study: Achieving ISO Class 5 Compliance in HVAC Maintenance

TechClean Solutions, a leading HVAC engineering firm specializing in cleanroom environments, faced a significant challenge when tasked with maintaining the HVAC systems in a pharmaceutical manufacturing facility. The client required strict adherence to ISO Class 5 standards during all maintenance activities to prevent product contamination.

Challenge: Maintain ISO Class 5 compliance during HVAC maintenance while minimizing downtime and contamination risks.

Solution: TechClean Solutions implemented a comprehensive strategy centered around the use of high-quality laminar flow hood garments for their maintenance team. They partnered with a reputable supplier to provide garments with ≤0.5μm particle emission ratings and conducted extensive training on proper usage and cleanroom protocols.

Implementation:

- Introduced laminar flow hood garments for all maintenance personnel

- Developed strict donning and doffing procedures

- Established a regular garment inspection and replacement schedule

- Integrated garment usage into standard operating procedures

- Conducted regular particle count testing during maintenance activities

Results:

- 98% reduction in particle counts during maintenance procedures

- 30% decrease in overall maintenance time due to reduced decontamination needs

- Zero incidents of product contamination attributed to HVAC maintenance over a 12-month period

- Successful passing of all ISO Class 5 compliance audits

- 25% reduction in annual costs associated with cleanroom decontamination

This case study demonstrates the significant impact that proper use of laminar flow hood garments can have on maintaining ISO Class 5 standards in HVAC maintenance scenarios.

Ofte stillede spørgsmål

What are laminar flow hood garments?

Laminar flow hood garments are specialized cleanroom attire designed to minimize particle emission and maintain cleanliness in controlled environments, particularly in areas requiring laminar airflow.

How do laminar flow garments help maintain ISO Class 5 standards?

These garments are engineered to emit extremely low levels of particles (≤0.5μm), helping to maintain the strict particle count limits required in ISO Class 5 environments.

Can these garments be reused, and how should they be cleaned?

Many laminar flow garments are designed for reuse. They should be cleaned according to manufacturer specifications, typically involving specialized laundering processes in cleanroom-compatible facilities.

Are laminar flow hood garments suitable for all HVAC systems?

While these garments are beneficial in many cleanroom HVAC applications, they are particularly crucial for systems in ISO Class 5 or stricter environments. Consult with a specialist to determine the most appropriate garments for your specific HVAC system and cleanroom class.

What certifications do these garments comply with?

High-quality laminar flow garments typically comply with ISO 14644-1 standards for cleanrooms and associated controlled environments. They may also meet specific industry standards such as IEST-RP-CC003 for garment systems in cleanrooms.

Maintaining ISO Class 5 standards in cleanroom environments is a critical responsibility for HVAC engineers. By implementing high-quality laminar flow hood garments and following best practices, engineers can ensure compliance, enhance efficiency, and minimize contamination risks during maintenance activities.

Are you looking to improve your facility’s contamination control strategies and ensure ISO Class 5 compliance? Request a Facility Assessment today and discover how our expert solutions can optimize your cleanroom operations.