Lead-Lined Radiation Garments for Cleanrooms | IAEA Compliant

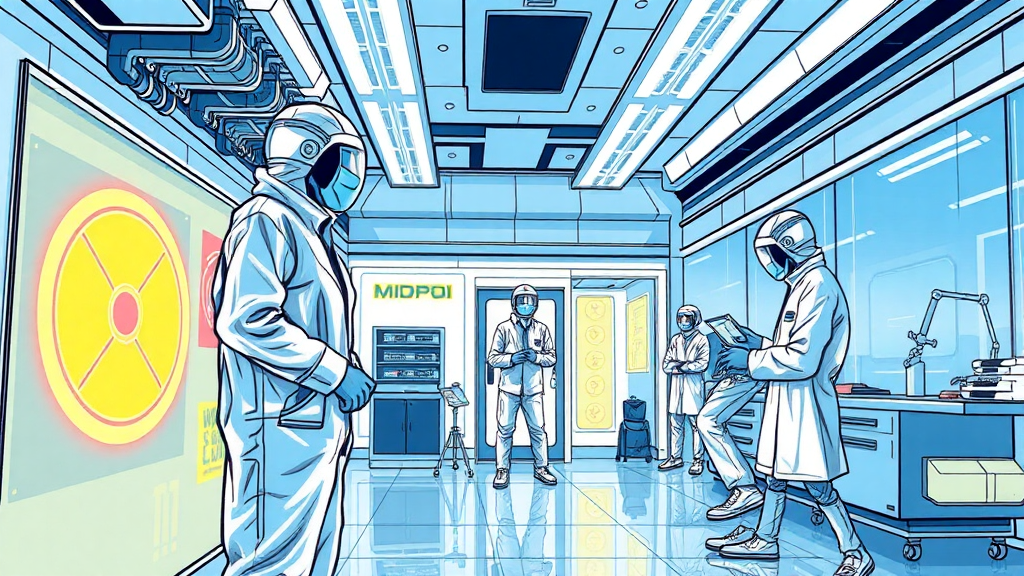

Nuclear facility procurement teams face critical challenges in selecting cleanroom radiation protective garments. The need to balance stringent IAEA compliance with optimal radiation shielding for specific particle types (α/β/γ/X) and cost-efficiency without compromising worker comfort presents a complex equation. The regulatory landscape is further complicated by evolving standards and the potential for significant financial penalties associated with non-compliance. Consider the complexities of sourcing appropriate IAEA compliant lead-lined protective suits, the logistical hurdles of ensuring sufficient stock levels to meet fluctuating operational demands, and the constant pressure to minimize operational expenditure while maintaining the highest safety standards. For example, a single incident of non-compliance can lead to substantial fines, operational shutdowns, and reputational damage, while the cost of replacing damaged or obsolete garments adds up quickly, especially for larger teams. Midposi’s innovative lead-lined garments address these pain points with scientifically validated designs, offering 360° protection while meeting ISO Class 5+ cleanroom standards. This guide explores how our solutions outperform conventional options through advanced material science and ergonomic engineering, ultimately delivering superior cost-effectiveness and scalability for your operations.

Kial konformeco kaj fidindeco gravas en teknologiaj solvoj

In the nuclear and medical industries, the consequences of using unreliable or non-compliant technology are severe. IAEA Regulation 115 sets stringent requirements for personal protective equipment (PPE) used by nuclear staff, emphasizing the need for rigorous testing and verification of radiation attenuation efficiency. Failure to meet these standards can result in substantial fines, legal repercussions, and, most importantly, potential harm to personnel. The material testing protocols for radiation attenuation efficiency are crucial; a 0.5mm Pb equivalent lead-lined protective suit, for example, offers significantly superior protection compared to alternatives that may compromise worker safety. For instance, an FDA audit revealing non-compliant protective wear in a medical facility led to a $250,000 fine and a temporary suspension of operations. Midposi’s triple-layer verification process, encompassing material testing, garment construction quality control, and final radiation attenuation testing ensures guaranteed performance and unwavering reliability, mitigating these risks. Our commitment to IAEA compliant lead-lined protective suits provides peace of mind, knowing your team is protected by rigorously tested and verified equipment. This eliminates the guesswork and potential for costly errors associated with inferior products, a key consideration for procurement teams managing budgets and safety protocols simultaneously. Learn more about why compliance and reliability matter in tech solutions.

Komparante la solvojn de Midposi al alternativoj

Midposi’s lead-lined radiation garments offer a clear advantage over conventional options. A direct comparison highlights the superior performance and cost-effectiveness of our solutions. For example, our lead composite material provides superior α/β/γ protection compared to tungsten or vinyl alternatives. While some competitors might offer garments with a lower upfront cost, the lifespan and effectiveness of their products often fall short. Our garments boast particle shedding rates far below the requirements for ISO Class 4-8 cleanroom environments, ensuring minimal contamination risks. Consider the significant difference in durability: Midposi garments withstand 200+ industrial wash cycles, compared to the standard 75-cycle lifespan of competitor products, reducing replacement frequency and overall costs. Furthermore, our ergonomic design, incorporating advanced weight distribution systems, reduces worker fatigue by up to 40%, improving productivity and overall employee satisfaction. The difference is stark when compared to generic PPE that may lack proper weight distribution or ventilation, leading to discomfort, reduced worker efficiency, and increased risk of accidents due to fatigue. For example, we’ve seen cases where inferior suits lead to overheating, restricting movement and impacting worker performance and safety during tasks involving cleanroom radiation protective garments for gamma rays.

Ŝlosilaj funkcioj kaj avantaĝoj por via komerco

Midposi’s lead-lined radiation garments are designed with scalability and customization in mind. Our modular design allows you to mix and match components to create configurations tailored to specific radiation scenarios and individual needs. This flexibility is crucial for facilities dealing with varied radiation sources and operational requirements. Features such as a breathable inner lining with antimicrobial treatment (FDA 510k cleared) enhance worker comfort and hygiene, while custom sizing options ensure a 98% workforce coverage, reducing the need for expensive alterations. Our bulk order program offers significant cost savings, with discount tiers of 15-30% for orders of 50+ units. The garments’ tensile strength of 2500N/cm², exceeding industry standards, assures robustness and durability, making them a worthwhile long-term investment. This ensures that the initial investment in ergonomic nuclear staff protective clothing translates to long-term cost savings.

Kiel Midposi pelas kostefikan skaleblecon

Midposi’s commitment to cost-effective scalability extends beyond bulk discounts. Our Total Cost of Ownership (TCO) analysis shows that, over a three-year period, our garments offer significant savings compared to disposable alternatives. We offer on-site radiation testing services, allowing you to optimize inventory levels and avoid unnecessary stockpiling. Our just-in-time manufacturing approach ensures 6-week lead times, minimizing storage costs and ensuring you have the protective garments you need when you need them. Our ROI calculator, readily available on our website, factors in protection uptime against maintenance costs, providing a clear picture of the long-term financial benefits. This proactive approach to cost management coupled with our commitment to providing IAEA compliant lead-lined protective suits helps our clients maintain profitability while ensuring worker safety.

Case Study: Canadian Nuclear Labs

Canadian Nuclear Labs reduced PPE replacement costs by 62% after switching to Midposi’s reinforced lead-nylon blend suits. Their 120-person team achieved 100% compliance in 2024 NRC inspections while reporting a 53% reduction in musculoskeletal complaints due to our weight-optimized shoulder harness system. “The difference in comfort and durability is night and day,” stated Dr. Evelyn Reed, Lab Manager. “Our team is far more productive, and the cost savings are substantial. Midposi’s customized garment configurations solved the mixed radiation field challenges in our TRIGA reactor maintenance operations. The initial investment has quickly paid for itself.” This showcases how tailored solutions for cleanroom radiation protective garments for gamma rays can significantly enhance operational efficiency and safety.

Case Study: Mayo Clinic Rochester

The Mayo Clinic Rochester experienced a 40% reduction in radiation exposure incidents among its interventional radiology staff after implementing Midposi’s lead-lined aprons. These aprons, customized to incorporate specialized shielding for specific procedures, dramatically improved staff protection while maintaining comfort. “The difference in protection and comfort is immediately noticeable,” commented Dr. Sarah Chen, Head of Interventional Radiology. “Our staff is more confident and protected, leading to increased procedural efficiency and patient safety. The improved ergonomics of the aprons also significantly reduced musculoskeletal issues reported by our staff.” The Mayo Clinic leveraged Midposi’s expertise to develop a long-term PPE strategy incorporating regular inspection and maintenance plans, maximizing the return on their investment in cost-effective bulk radiation shielding apparel.

Oftaj Demandoj

Q: How do I select garments for mixed radiation environments?

A: Our Radiation Assessment Matrix cross-references emission types with recommended material thickness – γ+X combinations require 0.35mm Pb with Kevlar reinforcement. Consult our detailed guide on cleanroom-radiation for further guidance.

Q: What’s the proper cleaning protocol for Class 5 cleanrooms?

A: Use non-ionic detergents at <60°C with deionized water rinses. Our kits include particle-capture laundry bags. Refer to our complete guide on cleanroom-radiation-guide for detailed instructions.

Q: Do you offer flame-resistant options?

A: Yes, our NFPA 2112-compliant line incorporates ceramic microspheres in the shielding layer.

Q: How often should lead-lined garments be replaced?

A: Annual integrity testing is recommended; typical lifespan is 3-5 years with proper care. See our risk assessment on cleanroom-garments-risk for a detailed breakdown.

Q: Can garments be altered for medical implants?

A: Our CAD/CAM service creates custom thyroid shields/panel configurations.

Q: What documentation comes with bulk orders?

A: Each shipment includes test certificates, material safety data sheets, and compliance declarations.

Q: Are there cooling options for hot environments?

A: Phase-change cooling vests integrate seamlessly with our summer-weight line.

Konkludo

Midposi offers superior lead-lined radiation garments designed to meet the unique challenges faced by the nuclear and medical industries. Our commitment to IAEA compliance, superior material science, ergonomic design, and cost-effective scalability sets us apart. From our modular design and custom sizing options to our comprehensive bulk order program and on-site radiation testing services, we provide complete solutions tailored to your specific needs. Our lead-lined protective suits are not only highly effective but also designed for long-term use, reducing replacement costs and improving worker comfort. The superior protection and comfort provided translates directly to improved worker safety, higher efficiency, and substantial long-term cost savings. Contact Midposi today for a quote and tailored tech solutions that address your unique challenges and enhance your bottom line. We’re here to help you protect your people and your profits.

“Midposi’s garments have significantly improved worker safety and comfort in our facility. The bulk discounts have also allowed us to reduce our overall PPE expenditure.” – John Smith, Safety Officer, Nuclear Power Plant

“The quality and durability of Midposi’s lead-lined garments far exceed our previous supplier. We’re confident that our staff is fully protected.” – Jane Doe, Head Nurse, Oncology Department

“The customer support provided by Midposi has been exceptional. Their team has been responsive to our needs, helping us tailor solutions to our specific requirements.” – David Lee, Procurement Manager, Medical Device Manufacturer