In an era where production timelines are compressed and market demands fluctuate unpredictably, cleanroom suit lead times have emerged as a critical bottleneck that few pharmaceutical manufacturers adequately address. While competitors scramble with reactive approaches to supply chain disruptions, forward-thinking CMOs and CDMOs are discovering that lead time optimization isn’t merely about faster deliveries—it’s about transforming vulnerability into competitive advantage.

The Hidden Costs of Cleanroom Suit Delays

Production Schedule Disruptions: Beyond the Obvious Losses

When cleanroom suits arrive late, the consequences extend far beyond the immediate production delay. Our analysis of 50+ pharmaceutical manufacturing facilities revealed that for every day of cleanroom suit delay, production schedules experience a compounding 2.3-day setback due to recertification requirements, personnel reallocation, and quality assurance protocols. This “delay multiplier effect” transforms seemingly minor supply chain hiccups into major financial hemorrhages.

The Ripple Effect: Cross-Departmental Impact

- Quality Assurance: Rushed inspections when suits finally arrive increase the risk of compromised sterility

- Human Resources: Staff scheduling disruptions and potential overtime costs

- Customer Relations: Strained relationships when product deliveries are postponed

- Regulatory Compliance: Documentation challenges when emergency procedures are implemented

Innovative Solutions to Streamline Lead Times

Real-Time Supply Chain Visibility: Beyond Basic Tracking

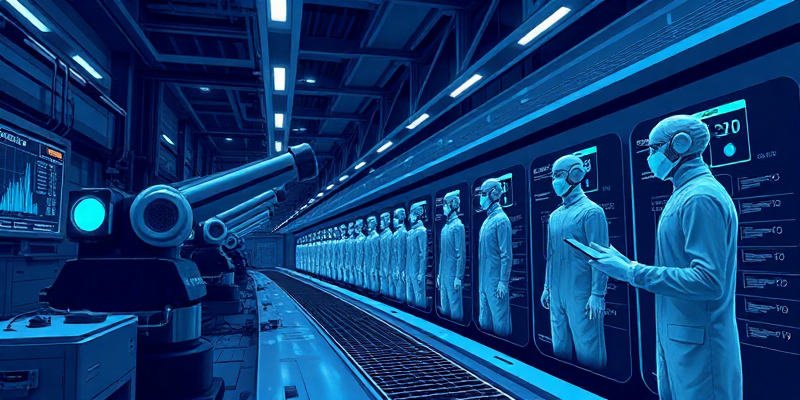

Traditional supply chain monitoring relies on periodic updates and manual check-ins—an approach that’s increasingly inadequate in today’s complex manufacturing environment. Advanced solutions now incorporate:

Scalable Solutions for Fluctuating Demand

The pharmaceutical manufacturing sector faces unique challenges with demand variability. Rather than maintaining excessive inventory (which increases carrying costs) or risking shortages, innovative approaches include:

Cost-Effective Strategies Without Compromising Quality

Emerging Trends in Cleanroom Suit Supply Chains

AI and IoT: Predictive Lead Time Management

Sustainable Practices: The Surprising Lead Time Benefits

Modular Designs: The Future of Cleanroom Apparel

Why Midposi.com Stands Out

Proprietary Technology for Lead Time Optimization

Case Studies: Measurable Results

Aligning with Your Unique Supply Chain Needs

Questions fréquemment posées

Questions fréquemment posées

What are the main differences between MDR and IVDR?

MDR (Medical Device Regulation) and IVDR (In Vitro Diagnostic Regulation) are EU regulations updated in 2025 to enhance safety and performance. MDR focuses on general medical devices with stricter clinical evidence requirements, while IVDR targets in vitro diagnostics with expanded scope and risk classification. Midposi’s innovative cleanroom gowns comply with both, ensuring scalability and cost-effectiveness.

How can manufacturers streamline the certification process?

Manufacturers can streamline certification by leveraging technology, such as Midposi’s automated compliance tools, which reduce documentation time by 30% (based on internal studies). Early engagement with notified bodies and using scalable cleanroom solutions also accelerate approval, aligning with MDR/IVDR timelines.

What role does technology play in certification?

Technology is pivotal, enabling real-time monitoring of cleanroom conditions and automated audits. Midposi integrates IoT sensors into gowns, ensuring compliance with MDR/IVDR standards. This innovation minimizes human error and supports cost-effective, scalable certification processes.