With an increasing focus on maximizing product yield, improving quality control and ensuring safety, companies in many industries are looking to install clean rooms or controlled environments in their facilities. Clean rooms are no longer limited to high-tech semiconductor manufacturing or university research laboratories. Today, clean rooms are used in all types of environments. But what is a clean room?

What Is Cleanroom?

- More than a room that is clean or a controlled environment, according to the ISO standard 14644-1 clean room definition, a clean room is defined as:

- “A room in which the concentration of airborne particles is controlled, and which is constructed and used in a manner to minimize the introduction, generation, and retention of particles inside the room and in which other relevant parameters, e.g. temperature, humidity, and pressure, are controlled as necessary”

- Clean room, in manufacturing and research, dust-free working area with strict temperature and humidity control that is of vital importance in the manufacture of equipment sensitive to environmental contamination, such as components for electronic and aerospace systems. Seamless plastic walls and ceilings, rounded corners, external lighting and wiring, a continuous influx of dust-free air, and daily cleaning are characteristic features. Clean-room workers wear special clothing, including head coverings, and, on entering, pass through an air blast, or air shower, to remove particles. Workpieces for assembly enter through an airlock.

- So, In the most simplistic terms, a clean room is a controlled environment where air and surface contamination is constantly monitored and strictly controlled, has undergone many improvements and refinements since 1962. These rooms are used in the semiconductor and chip industry, in the pharmaceutical and food industry, and also in electronic device manufacturing. The small particles in the ambient air that pose no danger to humans can still damage, contaminate or even destroy products from the aforementioned industries.

What Is Cleanroom Classifications?

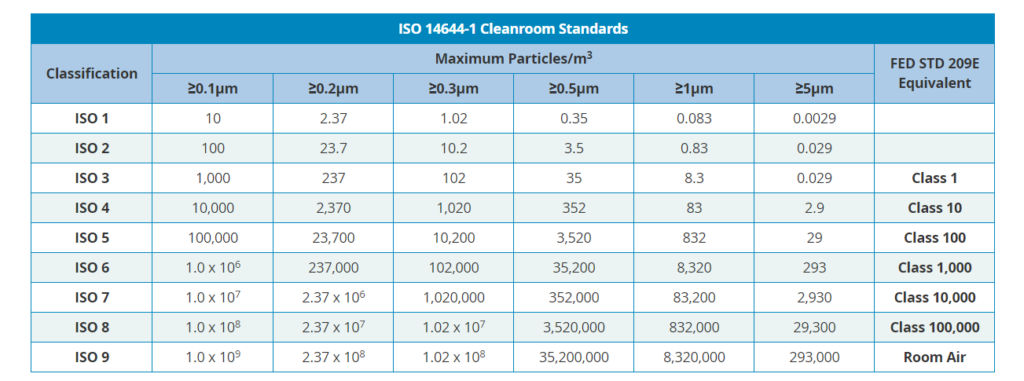

Cleanroom classifications are an important part of cleanroom design, development and daily use. They regulate the cleanliness of a cleanroom and are defined by the allowable contamination based on particle count and size and the necessary air exchange rate based on the cleanroom’s classification level. For example, let’s say your cleanroom must meet the ISO Class 6 level of 35,200 parts per cubic meter. This means that there cannot be more than 35,200 particles per cubic meter of cleanroom space in your cleanroom that exceed 0.5 microns in size. As a size reference, a typical measurement of the end of a human hair can be anywhere from 60 to 100 microns. Particles as small as 0.5 microns are invisible to the human eye, which is why we need multiple initiatives to control them.

ISO 14644-1 and ISO 14698

- Cleanrooms are classified by how clean the air is within the controller environment. The cleanroom class is based on the number and size of particles per cubic meter of air to determine the cleanliness class the room meets. The primary authority in the United States and Canada is the ISO classification system ISO 14644-1.

- This ISO standard includes these clean room classes : ISO 1, ISO 2, ISO 3, ISO 4, ISO 5, ISO 6, ISO 7, ISO 8 and ISO 9. ISO 1 is the “cleanest” class and ISO 9 is the “dirtiest” class. Even if it’s classified as the “dirtiest” class, the ISO 9 clean room environment is cleaner than a regular room.

- The most common ISO clean room classes are ISO 7 and ISO 8. The Federal Standard 209 ( FS 209E ) equivalent for these ISO classes are Class 10,000 and Class 100 000.

- The old Federal Standard FED-STD-209E ( FS 209E ) was a United States federal standard. It includes these clean room classes : Class 100,000; Class 10,000; Class 1,000; Class 100; Class 10; Class 1. It was officially cancelled by the General Services Administration on November 29, 2001, but is still widely used.

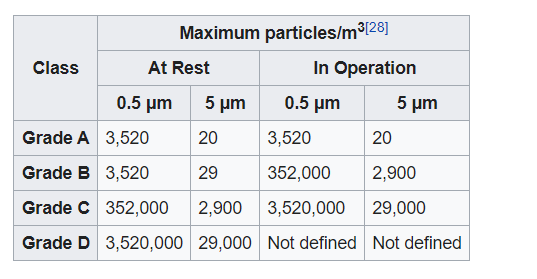

- Clean rooms must also follow industry-specific and regional standards. For example, EU GMP (A-B-C-D), applies to pharmaceutical products and USP (795, 797 and 800) to compounding pharmacies.

- Cleanrooms are classified according to the number and size of particles permitted per volume of air. Large numbers like “class 100” or “class 1000” refer to FED_STD-209E, and denote the number of particles of size 0.5 µm or larger permitted per cubic foot of air. The standard also allows interpolation, so it is possible to describe e.g. “class 2000.”

- Small numbers refer to ISO 14644-1 standards, which specify the decimal logarithm of the number of particles 0.1 µm or larger permitted per cubic metre of air. So, for example, an ISO class 5 cleanroom has at most 10^5 = 100,000 particles per m³.

- Both FS 209E and ISO 14644-1 assume log-log relationships between particle size and particle concentration. For that reason, there is no such thing as zero particle concentration. Ordinary room air is approximately class 1,000,000 or ISO 9.

EU GMP classification

EU GMP guidelines are more stringent than others, requiring cleanrooms to meet particle counts at operation (during manufacturing process) and at rest (when manufacturing process is not carried out, but room AHU is on).

What Is The ISO 14644 Approximate Approximate Equivalent For The EU GMP Grades?

We’ve noticed that we frequently get asked which ISO 14644 Classification is equivalent to EU GMP Grades for zones or cleanrooms, so we’ve put together a handy breakdown below.

- EU GMP Grade A is equivalent to class 100 or ISO 5

- EU GMP Grade B is also equivalent to class 100 or ISO 5

- EU GMP Grade C is equivalent to class 10,000 or ISO 7

- EU GMP Grade D is equivalent to class 100,000 or ISO 8

Where are cleanrooms used?

There are a variety of industries that require the use of clean rooms and depending on the work being done, will determine what ISO rating the room needs. When clean rooms were first used, it was usually in the high tech semiconductor industry, university research and life science labs. However, there are many other industries that utilize cleanrooms. We now list the industries that currently require the use of cleanrooms as follows.

Electronic Part Production

Anyone who works with computers will know that certain factors can cause a great deal of damage, including temperature, humidity and static electricity. In a cleanroom, these factors can directly affect the manufacture of a variety of different electronic components. Cleanrooms in this industry use several different cleanroom products such as anti-static coveralls and white coats, anti-static wipes, ESD (electrostatic discharge) cleaning products, ESD flooring and bench mats, and more. Electronics cleanrooms are typically in the Class 1 to Class 6 range.

Biotechnology

Anyone who works with computers will know that certain factors can cause a great deal of damage, including temperature, humidity and static electricity. In a cleanroom, these factors can directly affect the manufacture of a variety of different electronic components. Cleanrooms in this industry use several different cleanroom products such as anti-static coveralls and white coats, anti-static wipes, ESD (electrostatic discharge) cleaning products, ESD flooring and bench mats, and more. Electronics cleanrooms are typically in the Class 1 to Class 6 range.

Life Sciences

Similar to the biotechnology field, the life sciences industry stores and handles fluids and cells containing organic substances that are highly sensitive to external contamination. Pharmaceutical and other life science applications may also handle hazardous chemicals and compounds. Clean rooms in the life sciences are also designated between ISO Class 5 and Class 8.

Food Manufacturing

Food manufacturing industry is relatively new use for the cleanroom. It requires high hygiene standards to ensure that bacteria, fungi, or mold cannot develop and grow. To create an ideal environment, humidity, moisture-levels, temperature, air velocity, and air pressure need to be regulated. Cleanrooms in the food manufacturing industries require gloves, face masks, safety glasses, coveralls, shoe covers, and more. Because certain foods have varying levels of sensitivity, the ISO Class can range, but must meet ISO 6.

Automotive

The automotive industry has undergone significant changes since the first commercial vehicle was introduced. Modern automobiles consist of sensitive circuitry and computer components that are susceptible to damage from adverse environmental conditions during fabrication methods. Cleanrooms in the automotive industry typically fall between Class 6 and Class 9, depending on the component being produced.

Aerospace

The aerospace industry relies on cleanroom environments and their state-of-the-art enhancements to conduct experiments and create products such as space-faring lasers. Creating aerospace tools like lasers requires a controlled environment so that no contaminants or pollutants can damage the tool or product itself used in the manufacturing process. In the case of spaceflight lasers, absolute precision is essential. Some of these lasers are used to charge the vehicle’s batteries. Other aerospace lasers are designed with an eye toward ablation, that is, lasers used to vaporize space debris in Earth orbit.

Optics

Most people are happy when they capture a great photo on their smartphone, but those lenses, of course, the high-end lenses for professional cameras must be manufactured using clean room technology. The manufacture of lenses requires strict particle contamination control as well as humidity and temperature control and shock control protocols. The clean room environment allows technicians to create lenses that allow us to capture the timeless smiles of our loved ones or the beautiful landscapes we capture while on vacation.

Nanotechnology

While some people think of nanotechnology cleanrooms as boutique cleanrooms dedicated to electronics and semiconductor manufacturing, nanotechnology cleanrooms are actually used in many types of industries and their applications are used for fuel cells in addition to food. In an increasingly green world, cleanrooms dedicated to nanotechnology are now producing nanotechnology solar cells. These cells could have a significant impact on sustainability initiatives around the world, as they will be significantly less expensive to manufacture than traditional solar cells.

University Labs & Research Facilities

It may be unbelievable, but the mere presence of a few extra particles can throw even the most carefully designed experiment out of balance. In order to get clean results, all variables that could affect the experiment must be removed. Cleanrooms foster this contamination-free environment and therefore allow for experiments related to a wide range of science and technology. Cleanrooms provide a constant that helps researchers reduce or even eliminate cross-contamination or those variables that could hinder accurate results.

Military Applications

The military, as well as various government agencies, rely on clean rooms for many projects and experiments. In fact, if the James Bond character were real, his various gadgets would likely have been made in a cleanroom environment. Today, the military uses cleanroom laboratories to develop future technological systems while enhancing today’s technological equipment. For example, creating a new innovative material, such as a barrier to prevent pilots from being exposed to too much noise, is just one small aspect of the military’s use of cleanrooms.

How To Promperly Enter a Cleanroom

Need to fully understand the purpose of cleanroom protocols

need to know what level of cleanroom you are entering.

recognize that humans are usually the greatest source of contamination in a cleanroom

Movements increase the risk of cleanroom contamination exponentially. This is because humans emit thousands of particles as they move. Therefore, once your employees get into the cleanroom space, their movement should be minimal or none at all. If they must move, they should do so slowly.

Do not bring cosmetics, hairspray, perfume or cologne into the cleanroom.

Wear appropriate cleanroom clothing for the class of cleanroom. Cleanroom Clothing that are too small or too large could increase the risk of contamination. Employees should also be trained on how to seal all the gaps between clothing. This includes tucking hoods into coveralls, sleeves into gloves, and coveralls into boots.

Clean or change your shoes when entering the cleanroom. It is a good idea to have a pair of shoes used only in the cleanroom. If they change into this even before getting into the gowning area, there’s a lower chance of contaminants getting tracked into the workspace.

Put away personal items that you would not bring into the cleanroom.

Discard candy, gum, or anything else you have in your mouth. Should not eat in the cleanroom

Put on your cleanroom gear in the correct order.

If there is an air shower room, walk through it and step on any extra rubber mats as you enter.

Replace any cleanroom clothing that has been worn or soiled

Remove cleanroom garments in the reverse order you put them on

How to protect your staffs in cleanroom

How to behave

- Always think of safety first!

- Always wear the required cleanroom attire

- Change you cleanroom gown at least once a week

- Respect a comfort safety zone around people working in the cleanroom

- The maximum number of people in each of the two cleanrooms is 8 (4 as a consequense of COVID-19), providing that people are distibuted at different fumehoods and tools

- When you work at the fume hoods:

- Use slow movements (to avoid turbulence)

- Reduce the amount of equipment and bottles in the bench

- Operate with sash as low as possible (Always below arrow marking max sash height)

- Keep the worksurface tidy

- Clean up after use

- If you must leave a process unattended, please limit the time and attach a note with name, contact info, and return time.

- Wash labware after use with Milli-Q water and hang to dry on rack

- No food or drinks allowed in the cleanroom

- Broken glass must be cleaned and disposed of in the glass bins

- No earphones! You must be able to hear and see to act safely

How To Dress The Cleanroom Suits?

- When working in the cleanroom, you must always wear cleanroom attire, and when working with acids or dangerous chemicals, you must also wear personal protective equipment (PPE). Cleanroom attire and PPE have different purposes. Clean room attire is not PPE. You wear cleanroom attire to protect samples from dust generated by you, and you wear PPE to protect you from chemicals.

- To minimize particle generation your personal clothes and hair must be totally covered from the lower edge of the clean room coat and up. Long hair must be tucked under the hood and neither headscarves nor hair must stick out or block your vision.

- Oversized trousers or floor long dresses pose a safety risk as you may trip while handling chemicals and is thus not allowed. Clothing that contains excessive fringe or even overly loose-fitting clothing may be ruled to be unsafe. Open toed shoes are accepted.

- The use of contact lenses is not recommended in the lab. Contact lenses make it difficult to wash the eyes in case of splashes. If you choose to wear them you should alert other cleanroom users. Other users need to know that lenses will need to be removed if you do get something in your eye

- Please note that you are required to strip your clothes when using the safety shower. Not removing contaminated clothes will make the situation worse. If you are not comfortable with this, you should not enter the lab.

Cleanroom Attire

The required cleanroom attire is:

- Hair cover

- Safety glasses, even over normal glasses. They may only be removed when using the microscopes.

- Beard cover if you have a beard or stubble over 3 mm long

- Cleanroom gown

- Gloves

- Shoe covers

Personal Protective Equipment

- Further required PPE when working with dangerous chemicals:

- Apron

- General chemical work: Nitrile gloves

- Strong acids/chemicals: Nitrile + sleeve covers + tri-polymer protective sleeves

- Fumehood sash kept low